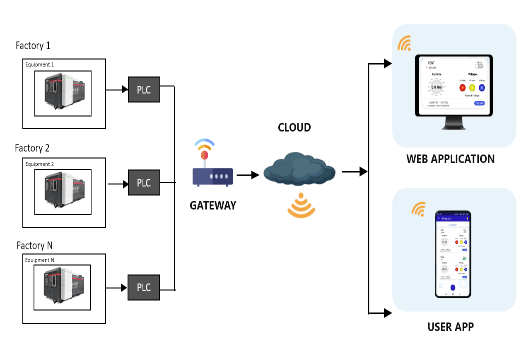

Delpheon OEE helps monitor equipment health, availability, reliability and utilisation, which helps to formulate efficient maintenance plans. It also helps differentiates between equipment and process issues thus reducing unnecessary maintenance activities.